Unlocking the Power of Liquid Cooling: Separating Hype from Reality

Liquid cooling in data centers offers a plethora of advantages, whether it's in the form of cold plate or immersion technology. One of its primary benefits is the potential for enhanced energy efficiency, including repurposing the extracted heat for other uses. These can include heating for residential purposes, such as an apartment building, or for commercial purposes, such as aiding in crop cultivation on farms.

However, it's important to acknowledge that current liquid cooling systems face challenges when it comes to efficiently utilizing excess heat for other purposes. What’s more, liquid cooling isn’t a panacea for all cooling issues. Implementing and managing such systems, including alongside traditional air cooling, requires a deep understanding of the technology, associated challenges, and limitations. Data center operators should utilize complementary tools, like data center digital twins, that can assist with deployment decisions and analysis.

Overcoming Psychological Barriers

Historically, the association of implementing liquid cooling with potential electrical hazards has hindered its widespread adoption. However, modern solutions have mitigated these risks through innovations like dripless quick connectors and negative pressure systems that prevent liquid from leaking into the data center. These innovations have made liquid cooling considerably safer, but many operators are still nervous about using liquid systems. This attitude is changing but is not the only barrier to adoption.

Integration with Air-Cooled Facilities

For legacy data centers designed to use air cooling, integrating liquid cooling poses complex logistical challenges. Coordinating the intricate flow networks of both systems can lead to inefficiencies in air cooling, as the introduced liquid cooling may disrupt the desired hot air output. Legacy data centers have already invested heavily in air cooling systems, and retrofitting a new liquid cooling technology alongside the existing air-cooled infrastructure can be both costly and complex. With multiple systems in play, data center operators require detailed insight into how they will operate together.

Liquid Cooling Causing Strain on Operations

Even when not combined with air systems, liquid cooling introduces operational complexities when installing equipment. For a liquid cooling system, operators must establish fluid connections in addition to electrical ones, so more work is required to implement things operationally. For immersion systems, where computers are submerged in a bath of mineral oil or equivalent substances, the operational paradigm differs significantly from traditional air-cooled setups. This is the next challenge to cover.

Balancing the Challenges of Liquid Cooling Technology

In theory, immersion cooling could dissipate 100% of the heat generated by electronic chips into the coolant. This would seem to be the solution to data center cooling woes but it is unfortunately plagued with the potential of material incompatibility.

When electrical components are fully immersed in a cooling bath, they come into direct contact with the coolant, subjecting all solid materials within them to exposure to the coolant. Over time, this can lead to certain materials leaching into the liquid or being affected by it. For instance, insulating materials like plasticizers in wires can react with the coolant, causing degradation and brittleness. This material incompatibility issue inevitably affects the equipment’s longevity.

Furthermore, immersion cooling relies on buoyancy-driven flow to dissipate heat from the chips, as opposed to forced convection. This limitation implies that it may not be suitable for handling high power densities. As chips become more densely packed, immersion cooling might struggle to efficiently extract heat through buoyancy-driven mechanisms.

Cold plate technology presents an alternative solution, yet it also has its share of issues. The choice of coolant is critical here, as subpar coolant quality can lead to deposits and corrosion inside the cold plate, diminishing its heat transfer efficiency and rendering the cooling system less effective. Additionally, as the resistance to heat transfer increases between the chip and the coolant, chip temperatures can rise, potentially causing thermal issues and reduced chip performance.

Cold plate technology also cannot capture close to 100% of the heat, as some components may not be compatible with the heat removal channels. Even if 80-90% of the heat can be managed, a significant portion—for example, five to 10 kilowatts in a 50-kilowatt rack—still escapes into the surrounding environment. This limitation reduces the potential gains and keeps the overall cooling capacity comparable to traditional air-cooled data centers. Addressing excess heat from liquid-cooled equipment during failure scenarios remains a challenge.

As neither cold plate nor immersion technology has gained widespread adoption, data center owners and operators face the difficult task of weighing the challenges associated with each approach and selecting the most suitable option. In the short term, cold plate technology may gain more traction due to its easier implementation and avoidance of electronic immersion. However, it's still uncertain which technology will ultimately prevail, as the liquid cooling landscape is currently far from mature enough to make definitive predictions.

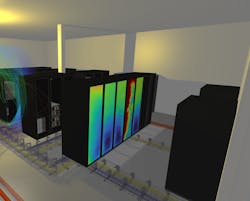

The Role of Digital Twin Technology

Regardless of which liquid cooling system a data center operator chooses, digital twin technology can help support decision-making. Digital twins are 3D virtual replicas of physical facilities that can assist with decisions on cooling deployment and management. The technology provides insights into aspects of a data center that would otherwise be difficult to observe or measure, including cooling dynamics. Operators can use digital twins to simulate different cooling systems and scenarios, optimizing their choices before implementing them in the real world. This creates a risk-free method for testing different cooling systems and making informed decisions, without the worry of causing any facility downtime.

A Positive Step Towards the Answer

Liquid cooling is not a complete solution to all cooling challenges, as both cold plate and immersion systems have their limitations. As such, ASHRAE has already introduced lower-temperature water classes to address the demands of modern chips. Nevertheless, these systems hold promise. Digital twins can assist data center operators in making confident decisions about which cooling scenarios best suit their needs and budgets and how to effectively deploy and manage them.

Mark Fenton is Senior Product Marketing Manager at Cadence Design Systems. Contact Cadence to learn more about its data center digital twin solutions.