How to Get Started on Your Immersion Cooling Journey

This concludes our article series on the fundamental shift that's taking place in the way the data center industry approaches cooling. This week, we'll present an immersion cooling readiness checklist, a few immersion cooling solutions, and explain how you can get started on the journey.

So far, we’ve covered the challenges in the data center industry that are pushing digital infrastructure leaders to examine immersion cooling solutions. We have also discussed a few myths that have been overcome with modern immersion cooling designs.

That said, let’s explore an immersion cooling readiness checklist.

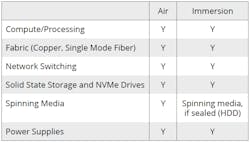

WHAT CAN BE SUBMERGED?

The first step in any immersion cooling project is understanding what from your environment can be submerged.

When working with immersion cooling, it’s important to note that there are different types to consider. For the sake of brevity, we’ll focus on direct immersion cooling, and let’s define that briefly.

Direct Liquid Cooling (immersion). An immersion cooling system directly connects the heat-producing components with a cooling liquid. Heat travels directly to the liquid through convection. Heat can be removed from the coolant in several ways. The coolant can be pumped to a heat exchanger, then cooled and recirculated. Alternatively, heat can transfer passively from the liquid to the enclosure, with the enclosure cooling by natural convection to the surrounding air; this is how power transformers on utility power lines are cooled.

Within the immersion cooling category are two types to consider:

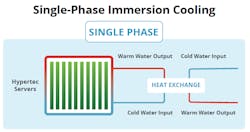

- Single-phase immersion cooling

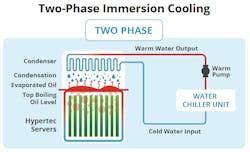

- Two-phase immersion

SINGLE PHASE COOLING: Like its two-phase counterpart, heat is transferred to the coolant through direct contact with server components. But, unlike two-phase immersion cooling, the coolant does not boil off. Instead, it remains in the liquid phase (hence the name) and is cooled via a heat exchanger in a cooling distribution unit (CDU). With the help of a heat exchanger, heat is transferred to a cooler water circuit. The technique guarantees little to no risk of the coolant evaporating.

TWO-PHASE COOLING: In a two-phase immersion cooled system, electronic components are submerged into a dielectric heat-transfer liquid bath, a much better heat conductor than air, water, or oil.

HYPERTEC’S CHOICE: Picking the right solution will revolve around your use case. However, following an assessment of single-phase and two-phase immersion systems, immersion cooling like Hypertec has decided to focus its roadmap on single-phase immersion technology entirely. The following table summarizes Hypertec’s comparison of the two technologies during their assessment.

The Immersion Cooling Journey: Innovation in Infrastructure

Before you jump on the immersion cooling bandwagon, it’s essential to understand your use cases and where immersion cooling can make a powerful impact. Remember, depending on the component and the solution, a liquid can remove only a portion of the heat. That said, not all equipment will or should be immersion-cooled. As mentioned earlier, the exciting part is that immersion cooling can create an all- encompassing solution where every component in your design is adequately cooled. So, designing around your use case is critical.

For those organizations looking to leverage immersion- born technology, it’s vital to look at immersion servers currently leading the market. For example, The Ciara Trident line of servers was the first to be developed specifically for single-phase immersion cooling. These servers offer ultra-high-density compute performance, up to 288 CPUs per 48U (144 nodes/18,432 cores). They are engineered to accommodate next-generation CPU, GPU, and FPGA cards.

Staying on the topic of servers, we also need to consider sustainability. The Ciara Trident server line is designed and manufactured for optimized liquid flow within single-phase immersion cooling, decreasing energy and water consumption and maximizing heat capture. The architecture leads to a reduction in carbon emissions by up to 40%. In addition, Hypertec will be using recycled materials to build the next- generation Ciara Trident systems, further reducing its carbon footprint.

Finally, immersion and air cooling will not be mutually exclusive in designing a good solution, and this means working with the right partners to design your ecosystem will be critical. Whether for HPC, rendering, edge computing analytics, AI, machine learning, or deep learning, immersion cooling has helped all these use cases thrive in the business world.

Data center leaders have also felt the impact of immersion cooling. “Partnering with Hypertec was a logical next step in offering our customers even more sustainable, cost-saving energy reducing from immersion cooling,” said Patrick Quirk, CTO at Nautilus Data Technologies. “The Hypertec immersion cooling solutions open the door for Nautilus customers to push the limits of increased Kilowatts for unrivaled power without increased electricity consumption.”

FINAL THOUGHTS

Data center technologies will only continue to evolve, and there is a certainty that data and data-driven systems will become the primary workload for many organizations. To support these use cases, leaders must rethink how they deploy critical infrastructure and what they use to deliver capacity, density, and efficiency.

To start your journey, it would be best to ask reflective questions about your business and current infrastructure designs. If you aim to work with high-density, data-driven workloads, immersion cooling is optimal for business and technological advantages. And when you can get to the data faster, you can leverage technology to better position your business. Immersion cooling can be a crucial driver for technology and business.

Download the full report, New Data Center Efficiency Imperatives: How Immersion Cooling is Evolving Density and Design, featuring Hypertech, for an expanded checklist that will help you become immersion ready.