The Importance of Rack Hygiene in High Density Data Centers

This week we conclude our article series on the challenges of keeping IT equipment cool in high density environments by exploring the importance of rack hygiene and the energy efficiency cost of airflow leakage.

Get the full report.

No matter how well a containment system is constructed and installed, its benefits can be reduced or negated if good “rack hygiene” practices are not followed. Poor practices can cause extreme cases of recirculation within the cabinet resulting in a 10-30°F rise in ITE intake temperatures above the cold aisle supply temperature.

Here are the basics that are relatively easy to implement, and at little or no cost.

- Use horizontal blanking plates for all empty spaces between ITE

- Wherever possible, keep ITE in the lower portion of the rack (especially important for uncontained or partial containment (end of aisle doors).

- Use vertical blanking components (flexible seals or brushes if cables from rear need to pass to front of ITE)

- Practice rear cable management to avoid blocking airflow. Use shorter cables (power and network) wherever possible.

- Install brushed collars (or similar devices) for all underfloor openings for power and network cables

In cases where there is a significant disparity in power density and exhaust airflow between opposing cabinets in a common hot aisle, the higher volume and velocity of the exiting airflow from high power cabinets can inhibit the low density cabinets from allowing the hot air to completely exit the cabinets which may cause them to overheat. If this occurs, an upward facing rear deflector on the higher density cabinet (or both cabinets) will help mitigate this issue.

If cabinet overheating occurs, an upward facing rear deflector on the higher density cabinet (or both cabinets) will help mitigate this issue.

Energy Efficiency Cost of Airflow Leakage

MoFlo, courtesy of TechnoGuard

In effect, any supply airflow from the cooling system that is not passing only through the ITE is considered bypass airflow and wasted cooling and fan energy. This is also called oversupply or over ventilation. While it is nearly impossible to accomplish this as a practical matter, to ensure that ITE airflow requirements are met, a certain amount of oversupply is necessary. However, unnecessary and preventable leakage should be controlled wherever possible or practical in high density environments.

While we have been discussing the technical aspects of airflow management, ultimately it also directly translates to increased or decreased fan energy usage and the cost of energy (see Fan Laws).

Fan Laws

There are three basic fan laws, which express the how the change in relative fan speed, static pressure and horsepower (power) interact.

Fan Law 1

The change in fan speed is proportional to the change in airflow

Fan Law 2

The change in static pressure (increase/decrease) with the square of the change in airflow

Fan Law 3

The fan power (increases/decrease) with the cube* of the change in airflow (fan speed). (*in reality the exponent of the actual fan curve may be slightly lower than a cube “3” exponent)

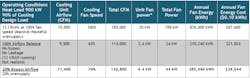

The chart in Table 9 shows how bypass airflow can impact the fan energy.

Table 9 – A hypothetical example of relative airflow vs fan power, simplified for clarity *(in reality the exponent of the actual fan curve will be slightly lower that the cube “3” exponent)

- Assumptions (simplified for clarity)

- Cooling System Design Rated 1,000 kW Critical load

- 12 Units Total N+2 redundancy

- Normal Conditions: Total of 12 CRAHs

- Failure mode: 10 CRAHs needed for critical Cooling Unit Specifications

- Cooling Unit Cooling Design Capacity 100 kW -Fan rated at 15,000 CFM fan power 10kW

- Cooling load 100% D-T 25°F (126 cfm/kW) 126,000 CFM: no leakage

- 90% IT Load (900 kW) IT D-T 25°F (126 cfm/kW) total required 113,400 CFM

- Design vs Actual Operating Conditions: As Table 9 demonstrates, 20% bypass airflow increases the fan energy use and cost by 83% (compared to a theoretical perfect match of CFM and D-T of IT equipment cooling system). While in reality it is virtually impossible for perfect airflow match to occur in an actual data center, the exponential nature of the third fan law shows the significant penalty or benefit for mitigating leakage which increases bypass airflow.

Download the entire paper, “High Density IT Cooling – Breaking the Thermal Boundaries“ courtesy of TechnoGuard, for exclusive content, including things to look for when selecting a data center provider.