Meeting Data Center Cooling Demands with Immersion Cooling Fluids: A Future-Ready Solution

Data center systems face unprecedented demand as artificial intelligence (AI), machine learning (ML), cloud computing, and high-performance computing (HPC) drive increases in energy use and heat generation, creating a need for new and innovative cooling solutions.

Immersion cooling offers a more efficient solution, using dielectric fluid to manage heat, and is becoming essential for data centers that face rapidly increasing power densities and high thermal design power (TDP).

In 2021, data centers consumed 1.5-2% of global electricity, and electricity demand is projected to double by 2026, largely driven by AI growth. Supporting this view is a recent report highlighting that US data center annual power consumption will grow from 4.4% (176 TWh) to between 6.7% and 12.0% (325 – 580 TWh) of total US electricity consumption by 2028.2 Advanced processors used in AI training, such as GPUs and TPUs, can generate heat levels that challenge traditional cooling methods. Immersion cooling, by directly submerging servers in a thermally conductive, dielectric liquid, offers data centers a sustainable solution that significantly reduces electricity and water usage, while delivering future-ready operational savings, enhanced performance and increased computation capacity at the same or lower power consumption.

Understanding immersion cooling technology

Immersion cooling delivers tangible benefits in energy and operational savings, as well as extended hardware lifespan. By eliminating the need for air handling units and fans, it can reduce power consumption and help data centers achieve pPUEs as low as 1.03. Operationally, immersion cooling could potentially deliver CAPEX savings of 20-35%, OPEX savings of 40-50%, and TCO savings of 30-40%, according to data from the Open Compute Project, Regional Summit 2023. For hardware, immersion cooling minimizes wear and tear by maintaining stable operating conditions.

Single-phase immersion cooling provides further advantages by eliminating liquid-to-gas phase changes, which simplifies system design, reduces component stress, and lowers maintenance requirements. Compared to direct-to-chip (D2C) cooling, which targets only processors and high-TDP chips, immersion cooling surrounds the entire server, allowing it to cool all components easily. This broader, comprehensive thermal management approach is increasingly essential as data center workloads intensify and components like memory, storage, and networking hardware generate significant heat in tandem with advanced processors. Immersion cooling; thus, enables data centers to handle rising computational demands effectively across the entire system.

Key insights from coolant performance studies

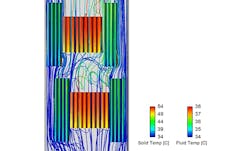

A common misconception in immersion cooling is that viscosity is the primary performance indicator for coolants. However, our internal studies and published literature from OCP have demonstrated that thermal conductivity and heat capacity are more critical, especially in forced convection applications where high flow rates and power densities are at play. Computational Fluid Dynamics (CFD) models and analytical tools can help optimize coolant flow through heat sinks, enabling engineers to optimize cooling performance without physical prototypes.

ExxonMobil proprietary models have shown that hydrocarbon-based coolants can outperform fluorocarbon coolants for single phase immersion cooling, particularly in high-flow scenarios involving high-TDP processors. These findings not only challenge traditional assumptions but underscore the importance of pairing the right fluid with optimized system designs. For example, our model predicts that EM DC 3235 Super will perform better than competitive products in high-TDP environments when flow rates through heat sinks are optimized. EM DC 3235 Super’s performance is primarily driven by its thermal properties, and its step out balance of viscosity and flash point make the product stand out from alternatives.

Sustainability and immersion cooling

For data centers, reducing energy consumption and water usage is as much about sustainability as it is about cost. Some immersion cooling systems today achieve partial Power Usage Effectiveness (pPUE) as low as 1.03, improving energy efficiency while lowering operational costs.

Environmental considerations include PFAS (per- and polyfluoroalkyl substances) coolants, which face scrutiny. In response, the industry is shifting to PFAS-free hydrocarbon fluids, which align with evolving regulations. With these eco-friendly alternatives, data centers can reduce their environmental footprint while scaling operations. As global regulations on emissions and water conservation intensify, immersion cooling may potentially assist data centers with achieving these regulations, while accommodating rising computational demands.

Overcoming challenges to adoption

Most server hardware today is still designed for air cooling, posing challenges for immersion cooling adoption. In some existing immersion cooling systems, cooling fluids often bypass the high heat generation components like CPUs and GPUs. Sometimes, as much as 90% of fluid may flow around parts requiring cooling rather than through them, limiting immersion cooling’s effectiveness.

To fully capitalize on immersion cooling benefits, hardware design must allow coolant to flow directly through the heat sinks, ensuring sufficient fluid reaches the high heat generating components. Servers must be designed specifically for immersion, with compatibility for fluid and heat sink optimization. Collaborative efforts among manufacturers, fluid developers, and data center operators will be essential to advance these hardware designs and maximize immersion cooling’s potential. Leading industry players recognize the need for systems optimized for immersion cooling, with programs like the Open Compute Project (OCP) establishing new guidelines to support adoption.

There is now a heightened emphasis on driving innovation in single-phase immersion cooling, paving the way for broader industry adoption. As the market aligns on standards, immersion cooling is set for wider industry adoption.

Conclusion

As data center workloads evolve, immersion cooling stands out as a vital solution for managing future computational loads efficiently. Its ability to reduce energy consumption, extend hardware life, and lower operational costs positions it as an essential strategy for the industry’s growth.

Continued research, cross-industry collaboration, and innovation in cooling fluids and hardware design will further enhance performance and efficiency, securing immersion cooling as a long-term solution for data centers. Now is the time for industry leaders to embrace these advancements and collaborate across the ecosystem, unlocking the full potential of immersion cooling.

This material is for information purposes only and should not construed as financial advice. ExxonMobil is not responsible for any errors or omissions, or for the results obtained from the use of this information. All information in the material below is provided "as is", with no guarantee of completeness, accuracy, timeliness or of the results obtained from the use of the information in this material.

About the Author

Weixue Tian

Weixue Tian is the Applied Research Department Manager in Lubricants Technology at ExxonMobil Engineering and Technology Company. In the area of data center cooling, Tian leads a team developing analytical and computational fluid dynamics models for optimizing and screening cooling fluids.

ExxonMobil Product Solutions is a leading global provider of innovative chemical products and solutions that support industries ranging from automotive to consumer goods. With a commitment to sustainability and cutting-edge technology, ExxonMobil collaborates with customers to create high-performance products that meet evolving market needs. For more information, visit ExxonMobil Product Solutions.