With the infrastructure required to deliver AI set to drive a 160% increase in data center power demand, data centers must reconcile AI’s surging energy requirements with existing capacity demands and strict sustainability goals. Many companies that initially rushed into AI, driven by competitive urgency, may need to reevaluate how to handle its energy impact. This shift will likely push organizations toward selective, high-value AI applications that provide stronger operational returns.

Even high-value AI applications will stretch data center capacity to its limits if not implemented carefully. Tools like digital twins will be essential for data centers to meet AI goals sustainably, allowing operators to proactively manage power, integrate renewable sources, and optimize cooling measures to meet AI’s GPU usage demands. With these advancements, data centers can help organizations make AI investments that are both impactful and environmentally responsible.

How Digital Twins Help with Futureproofing AI

Bringing high-density computation into any data center can have significant ramifications from a power, cooling, failover, and structural limits perspective. Many data center planners face the same problems as before AI, such as choosing between operational performance and speed, navigating increasing demands on capacity with stalling budgets, and maximizing capacity in fixed infrastructure, just on a much larger scale.

Digital twin technology enriches engineering expertise with powerful insights into data center performance and can help remedy many of these challenges. By implementing a digital twin of the data center, organizations can test multiple design configurations and validate the best capacity planning solution moving forward. With effective communication and the right tools, speed and quality can coexist in data center capacity planning. Digital twins that use computational fluid dynamics (CFD) simulation offer data center teams a practical path forward.

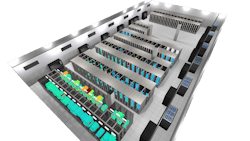

Comprehensive digital twins create a 3D virtual replica of the data center using a built-in CFD engine, IT asset lists, computer-aided design (CAD) floorplans, and monitoring data. Planners can propose asset changes in the digital twin, while Facilities Management can also predict the outcome of these changes in the same digital twin. The best digital twins enable two-way exchanges between the digital twin software and other data center management tools, such as DCIM and environmental monitoring systems. This ensures the digital twin has up-to-date information and can produce accurate, timely simulation results.

Digital twins are designed in this way to streamline the capacity planning process by ensuring that (1) all changes are validated using simulation and (2) all stakeholders are in communication with one another. As such, data center teams no longer have to choose between operational performance and speed. Simulation ensures the decision-making is sound and the process is seamless between teams.

Significantly, CFD-powered digital twins can simulate the physics of airflow delivery. With every deployment, the airflow delivery profile changes, whether from IT changes in the cabinets or modifications made to other parts of the facilities. Digital twins can also enrich data center power analysis by visualizing the entire power network from utility to IT. Simulation can be used to test breaker loadings for future deployments and test failure scenarios to ensure uninterrupted power can be supplied to every piece of equipment in the facility.

Given that the data center is an incredibly dynamic space, being able to visualize cooling, airflow, and power makes all the difference. Knowing how the data center will react to new configurations is essential to creating a robust data center that can navigate increasing capacity demands.

Being able to explore any “what-if” scenarios means that data center teams can ensure no option is left wasted or unexplored, so these teams can examine ways to maximize capacity despite fixed infrastructure and mitigate potential risks. This functionality can also be applied to improve energy efficiency and implement AI sustainably and effectively.

Removing Data Center Risk When Implementing New Technology

While the data center landscape continues to change, the core issues a data center must solve remain the same. Ultimately, a successful data center is one that is agile, cost-effective to run, and efficient. Data center digital twins allow stakeholders to explore all options or scenarios, predict potential outcomes, and feel satisfied with the knowledge that they are making the best decisions that equip their data center to adapt to future change without risk. Simulation provides stakeholders with a solid foundation to test new technologies, like AI, and make risk-free decisions to ensure data center longevity.

About the Author

Mark Fenton

Mark Fenton, Product Engineering Director at Cadence Design Systems, has accrued over 20 years’ experience pioneering the use of computational fluid dynamics (CFD) in the data center design and operations industry.

Cadence is a leader in electronic systems design, building upon more than 30 years of computational software expertise. The company applies its underlying Intelligent System Design strategy to deliver software, hardware, and IP that turn design concepts into reality. Cadence acquired Future Facilities in 2022 for its expert 6SigmaDCX and 6SigmaET simulation software suites to expand its electronics product portfolio and facilitate energy efficiency and performance optimization for the data center industry through digital twin technology – now Cadence Reality DC.