Leveraging Digital Twin Technology for Sustainable Data Center Performance

In an era where digital transformation is accelerating at an unprecedented pace, data center operators face the significant challenge of delivering increased processing power sustainably. Balancing these demands is no small feat, especially given the rapid advancements in artificial intelligence (AI) and the resultant rise in IT equipment densities.

The surge in high-performance applications and high-density IT equipment places immense pressure on data center systems. More powerful IT systems demand greater energy consumption. Further complicating the issue is the disparity in equipment densities across a single data center, making resource management a daunting task. Current data center management tools frequently fall short, unable to accurately predict the impact of deploying high-density IT hardware on the facility’s overall capacity to power and cool effectively. This uncertainty often forces operators to overcompensate, leading to higher energy costs.

Overcompensation in resource allocation is not merely a financial burden; it also contributes significantly to environmental concerns. With sustainability regulations like the Energy Efficiency Directive (EED) and Corporate Sustainability Reporting Directive (CSRD) becoming more common, data center operators will face additional pressure to track, report, and reduce power and cooling usage without compromising operational integrity. The question then arises: how can operators balance the conflicting demands of increased performance and sustainability?

Digital Twins for Data Center Operations

Digital twin technology offers a compelling solution to this multifaceted problem. A digital twin is a virtual model of a physical data center that allows operators to simulate and test planned changes before implementing them in the real world. This capability is invaluable for maximizing available capacity without risking the integrity of IT equipment. Key benefits of digital twin technology for data center operations include:

- Resource Efficiency: Operators can track and optimize the use of key resources. This can potentially delay the need for new data center construction, leading to significant cost savings.

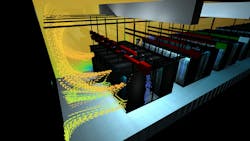

- Performance Visualization: Any planned changes to the physical data center can first be tested in the digital twin. By capturing and visualizing the effects of changes, operators can see the potential impact on performance and make necessary adjustments before risking actual hardware.

- Informed Decision-Making: Solutions like Cadence Reality DC use computational fluid dynamics (CFD) simulation to model complex thermal dynamics, cooling, and airflow. These insights allow managers and operators to assess the true capacity of their data centers, ensuring that they have access to the most important data when making effective, sustainable decisions.

One of the critical applications of digital twin technology is its ability to predict and manage cooling capacities effectively. Identical cooling capacities can yield vastly different performance outcomes depending on the data center’s layout. Visualizing these differences on a virtual platform allows operators to test various conditions safely, preventing stranded capacity and avoiding elevated temperatures from new deployments.

Navigate the Complexities of Modern Data Center Management

In short, the increasing density of IT equipment and the accelerating pace of digital transformation pose significant challenges for data center operators. Traditional management tools often fall short in predicting the impact of high-density deployments, leading to overcompensation and increased energy consumption. Digital twin technology offers a promising solution by enabling operators to simulate and optimize changes in a virtual environment, securing resource efficiency and sustainability initiatives.

Embracing digital twin technology can help operators navigate the complexities of modern data center management. By leveraging these advanced simulation tools, operators can achieve a balance between enhanced performance and sustainable operations. This approach not only ensures optimal data center performance but also aligns with the growing demand for energy efficiency.

About the Author

Dave King

Dave King, Senior Principal Product Engineer at Cadence Design Systems, has worked in the data center industry in a variety of roles since 2007 and is responsible for guiding Cadence Reality DC (previously 6SigmaDCX product line) to being the best-in-class tool for designing and managing the physical data center environment.

Cadence is a pivotal leader in electronic systems design, building upon more than 30 years of computational software expertise. The company applies its underlying Intelligent System Design strategy to deliver software, hardware, and IP that turn design concepts into reality. Cadence acquired Future Facilities in 2022 for its expert 6SigmaDCX and 6SigmaET simulation software suites to expand its electronics product portfolio and facilitate energy efficiency and performance optimization for the data center industry through digital twin technology – now Cadence Reality DC.