This concludes our article series on how modular design and sustainability both play a significant role in data center modernization efforts.

Keeping data centers cool might seem straightforward, but what happens when a massive heatwave occurs?

In 2022, the month of September brought record heat temperatures to the state of California. With thermometers ringing in as high as 116F (46.7C) in Sacramento, the state’s capital, the grid was under strain, and even reports of Twitter shutting down made their way to the headlines. These challenges were not just isolated to California. In July of the same year, the U.K. heatwave shut down Google and Oracle data centers.

In Stockton, CA, Nautilus saw the mercury tick up to the highest temperature recorded at 115 °F on September 6, 2022.

Understandably, all of the tenants in the data center were concerned mainly because of the news reports they were reading. However, both Nautilus and its facilities remained nice and cool.

While the Heat Was on, Data Center Ambient Temperatures Remained Stable

In the previous section, we discussed how Nautilus applied innovation to leveraging water to keep its facilities cool. During this massive heatwave, the design paid off. Nautilus kept its data center up, running, and functioning as it should. Nautilus ran the data center the same, and ambient temperatures averaged out at 82.9°F for that period (September 1-9), nearly 7° under the 89.6°F ASHRAE allowable standards.

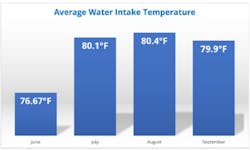

However, there was another concern. If it’s this hot outside, doesn’t the water heat up too? Because of the unique Nautilus design, the system extracts water from a deeper depth. As a result, short-term temperature fluctuations in the environment have little impact on the water’s temperature entering the facility. The water isn’t impacted because of water’s thermal absorption properties, the water flow and mixing rates, evaporative cooling, heat energy transfer to the underlying soil, and the fact that even when it is hot during the day, it does cool down at night. Let’s take a look at how September’s water temperatures so far compared with June, July, and August:

How to Become a Part of a More Significant, More Sustainable Data Center Solution

In California alone, Nautilus calculated the estimated water savings achieved from a statewide deployment of their water-cooling technology totals 14.83 million gallons daily.

They calculated this with the approximate number of M.W.s in the state and the newest data from the 2021 report from Lawrence Berkeley National Laboratory’s estimate of the U.S. data center’s direct onsite water consumption:

1300 MW in CA x 475.5 gallons per MW per hour = 618,150 gallons per hour // 14.83 million gallons per day

Here’s another critical point around direct water usage: According to research, only one- fourth of the volumetric water footprint of data centers is due to onsite water usage.

Yet, more than 40% of the water scarcity footprint is attributed to direct water consumption. The direct water consumption of data centers near the data center location is higher in areas with less available water than its indirect water consumption.

Why Modular? Why Now?

The designs we’ve discussed take a new approach to deploying critical infrastructure. The specific reasons why modular is important now are the following:

- Much faster time-to-market

- Reduction of risk

- Far greater density

- Reduction in deployment complexity

- Massive impacts on sustainability and water utilization

Leaders in the industry are taking note that these designs are at the forefront of how we bring infrastructure online.

Download the entire report, Modernizing Efficiency and Time-to-Market: A New Approach to Data Center Design, featuring Nautilus Data Technologies, for an exclusive look to the future of data center design.

About the Author