Data Center Design — From Legacy to Modern

This launches our article series on how modular design and sustainability both play a significant role in data center modernization efforts.

While we’re sure the subheading below the main title caught your attention, the topic of this paper will dive into just how much of an impact the past four years have had on the data center industry. And yes, floating data centers will be a crucial topic. 2020 was an eye- opening moment for everyone. In the technology space, leaders in the data center communities raced to ensure users had the digital tools they needed to succeed. The result? Today’s massive boom in digital infrastructure, time-to-market challenges, and even more reliance on critical systems.

But unlike digital booms in the past, something feels different today. The global data center market has witnessed a significant boost since the 2020 pandemic. The demand for data centers has increased because of the increased access to internet-related services aided by nationwide lockdowns imposed by governments worldwide.

Our need to be constantly connected has transformed this industry. Modernization efforts are being leveraged to improve speed-to-market while maintaining the quality of the infrastructure. Some are revolutionizing data center architecture by prefabricating upwards of 70% of their facilities in factories. They’re seeing this evolution as a digital infrastructure-as-an-assembly line.

Furthermore, the rapidly evolving competitiveness in the global market and advanced technologies have made it simpler and cheaper for enterprises to shift their workload to self-contained data centers.

However, with massive growth come growing pains. Challenges include demand vastly outstripping supply, legacy construction and deployment practices, and supply chain issues.

This special report article series will explore the current state of the data center industry and how modernization has impacted speed-to-market. Specifically, we’ll review new data centers and modular designs, how sustainability plays a significant role in modernization efforts, and how leaders look to the water when they run out of land.

Introduction

Welcome to the digital era where you are a digital citizen. Our reliance on new forms of communication, interaction, and doing business has evolved over the past decade. That evolution hit the accelerator over the past couple of years.

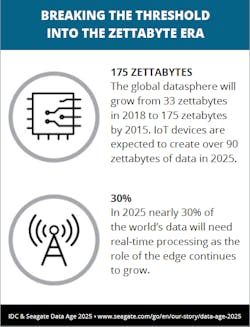

In 2012, we crossed into the zettabyte era, and that is, the data in our digital ecosystem, for the first time, exceeded a zettabyte. That number continues to increase today, with estimates pointing to around 175 zettabytes by 2025.

At the heart of all this is your data center. However, there has been a fundamental shift in how we deploy technology solutions and where digital modernization impacts physical infrastructure. Too often, we look at modernization efforts as server upgrades and new pieces of software.

However, modernization in the data center industry is far more than a server upgrade.

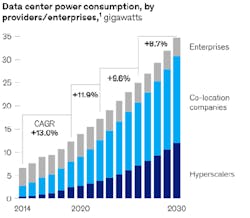

How Modernization is Impacting data center supply and demand

These last three years have been a masterclass in better understanding data center supply, demand, and construction challenges. A pandemic threw everything for a loop as demand for connected infrastructure skyrocketed, and that demand hasn’t slowed down. Consider this, in the U.S. market alone, demand—measured by power consumption to reflect the number of servers a data center can house—is expected to reach 35 gigawatts (G.W.) by 2030, up from 17 G.W. in 2022, according to McKinsey analysis (see image below). The United States accounts for roughly 40 percent of the global market.

Even still, we’re having trouble keeping up. In a recent DataCenterHawk report, we saw the North American primary market vacancy now averaging 4.4%, its lowest point ever. In Northern Virginia, that vacancy rate is closer to 1%, and this is the first time the average dropped below 5%. While a few markets with decent capacity are available to meet the demand, most are supply constrained, with data center operators looking at ways to increase.

US data center demand is forecast to grow by some 10 percent a year until 2030.

The supply chain isn’t helping. From a recent conference in September 2022, JLL discussed how challenges in delivering essential parts are challenging many traditional data center operators.

- Generators and enclosures are a 50+ week wait, and this is compared to 10-12 weeks pre-Q3

- UPS containers are a 45-50 week Compared to 8-12 weeks pre-Q3 2021.

- Chillers could cost you a wait of 70+ weeks compared to a week or less when working with dedicated inventory lead Even a standard lead time would be 16-18 weeks.

Between September and now, there has been some good news. Lead times are getting lower, but you’re still waiting two to three times longer than you would have in the past.

With this in mind, it’s essential to pivot and understand how we’re deploying today’s data centers and using modernization to our advantage. With modernization impacting digital infrastructure, it’s necessary to explore how our physical components are affected. This means looking more closely at modular infrastructure and sustainability and ensuring we properly leverage resources while improving ROI and a company’s speed-to-market.

Data Center Design — From Legacy to Modern

Organizations across industries are accelerating their digital transformations and looking toward data center leaders to help them adapt to a new normal where disruption could be around every corner. Modular construction methods have been modernizing data center projects for some time, but the impact of the past few years will undoubtedly put this at the forefront.

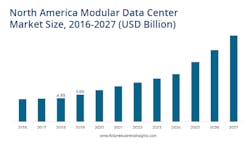

A recent report from Fortune Business Insights indicates that the global modular data center market size was $16.56 billion in 2019 and is projected to reach $65.55 billion by 2027.

Apart from cost savings, modular constructions benefit from reducing the number of people required onsite during the construction phase.

This shift into a more modular design directly results from digital modernization efforts impacting physical infrastructure.

For data center professionals, we are at the inception point of where digital modernization will be taking us. Let’s explore this a bit further.

Distributing Computing: Edge, 5G, IOT and More

As the potential next iteration of connectivity, 5G solutions have been widely marketed and discussed. But is this just a marketing fad? Will these technologies hit the mainstream? The short answer is yes. Beyond 4G LTE solutions, evolution is needed to connect and share rich content and critical workloads. So, since the first 5G network went live in April 2019, there have been many advancements and updates already.

According to Gartner, 5G is one of the main drivers of mobility. The 5G infrastructure market hit over $4 billion, with two-thirds of companies deploying 5G in 2020 and beyond.

According to Gartner, around 10% of enterprise- generated data is created and processed outside a traditional centralized data center or cloud. By 2025, Gartner predicts this figure will reach 50%. This means that services around the edge will continue to evolve and grow. This is also why you need to work with a partner to help you address common issues like consistency between deployments, reliability, remote installation, connectivity, monitoring and management, and security. Furthermore, the edge will require a broader focus on connectivity, telecommunications, and modular design to ensure the best possible experience.

Here’s another vital point: A recent report from Nokia indicated that over three-quarters (77%) of respondents found the use case of connected equipment and cloud- connected robotics appealing, as they are vital enablers of Industry 4.0.

Responding companies noted that leveraging 5G alongside connected IIOT allows them to “readily visualize the benefits of 5G for real-time monitoring and remote control of machines they can’t currently control remotely.”

These new trends bring to light emerging cloud and data center balance considerations. They also bring up new latency challenges and ensure that workloads are delivered as efficiently and resiliently as possible. Beyond edge computing, IoT, 5G, and the cloud, another massive trend impacts data center density, efficiency, and sustainability, and that is, ChatGPT.

Generative A.I. and the Data Center

You don’t have to look far to see a recent ChatGPT or generative A.I. reference. While these technologies are poised to impact our lives, they will also vastly change how we design dense and efficient data center solutions. The growth of these technologies has been nothing short of staggering. To put this into perspective, ChatGPT reached one million active users in 5 days. They reached this milestone faster than any other application in history.

However, a single ChatGPT session has so much behind it, and it takes over $15-20/hour to run machines supporting GPT functions. And while these systems do excellent time management, they still run 24 hours a day, seven days a week.

Here is a metric to think about. A single Google search can power a 100w lightbulb for 11 seconds. A single ChatGPT session consumes over 50-100 times more power than a single Google search. That’s a lot of lightbulbs. Generative A.I. and emerging machine learning neural network data models will consume more power. Further, these solutions will be a part of almost every data center model. The carbon footprint of these large-language models (LLM) will also grow.

Leaders in the data center industry have turned to modular architecture to support this growth, density, and sustainability requirements. However, modern modular ecosystems are much different than in the past. Now, leading solutions are highly dense, efficient, and built with sustainability at the forefront.

Modular Solutions Help You Keep Pace with Industry Innovation

To keep pace with this level of adoption, leaders are turning to new designs to help them stay ahead in a digital market. Mainly, they are trying to improve their speed-to-deployment to ensure they have the resources to keep the business ahead. A recent Business Wire report indicates that modular data centers are at least 60% faster to deploy and provide 13% or more cost savings than traditional data center power and cooling infrastructure. Hence, modular is also helping overcome the rising energy crises due to growing data and data center infrastructure. This is important because North America accounts for a significant market share of data centers. It is expanding its capacity with more than 411 MW, currently under construction or near completion.

Before we go further, let’s explore the new concepts around modular and why so many are leveraging this design.

What is Modular?

For the longest time, the concept of a modular data center solution has eluded definition, if not comprehension. A description and categorization of solutions have emerged through the short history of modular solutions and vendor marketing.

A dictionary definition hints at the data center adaptation of modular:

A self-contained, fast-scaling unit or item that can be combined or interchanged with others to create different shapes or designs.

A modular data center can be defined as more of an approach to data center design that incorporates contained units, many times in the form of prefabricated modules. The modular market started with an international standard procedure in the shape of an ISO (International Standards Organization) shipping container and has evolved into a market of vendors that produce everything from containers to various modular designed products and solutions for I.T., power, and cooling. Now, leaders in the modular data center industry are also building data center architectures that leverage water for cooling in some of the most innovative ways. We’ll cover this shortly. The modular industry’s innovation level has pushed many leaders to rethink how they deploy critical infrastructure. And this is excellent news for sustainability enthusiasts and those focusing on improving speed-to-market.

Shifting the Paradigm: All Things Modular

The idea of a modular I.T. solution quickly spread to the supporting infrastructure for a data center. Product manufacturers for power and cooling equipment began making modular solutions to complement modular I.T. deployments and act as a quick, easy, and standardized way to deliver their products to traditional data centers.

UPS, flywheels, generators, and chillers – all turnkey and containerized. A modular approach to supplying power and cooling presents many of the same benefits as a modularized I.T. solution. While not required to be in any particular form factor, many are delivered in a containerized solution.

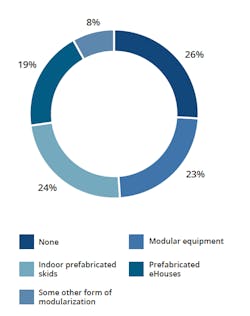

Consider this, a recent survey taken during the DCD Building at Scale conference also showed that 74 percent of data center professionals are already dealing with some modularization:

Looking further out, some modular data center leaders are building facilities on land and water. In the scenario of Nautilus Data Technologies, they build facilities on land or water. If built on land, it’s close to a body of water, and it’s for an excellent reason. Their closed- water loop technology utilizes nature’s cold water to keep racks cool under a vacuum. The significant part is that the water will never touch the I.T. load and is designed to maintain ASHRAE A1 Standards. We’ll cover this in a later article in our series. The point to grasp here is that the level of innovation around modular design is inspiring.

Download the entire report, Modernizing Efficiency and Time-to-Market: A New Approach to Data Center Design, featuring Nautilus Data Technologies, to learn more. In our next article, we'll explore key considerations for modular data centers.