How to Improve Data Center Sustainability and Lower Carbon Emissions

Companies worldwide are seeking new ways to offset the negative impacts of waste and greenhouse gas (GHG) emissions. Recently, Google, Amazon and Microsoft revealed future investments and strategies to lower carbon emissions. Although nothing is perfect, it’s a promising sign to see enterprise organizations take steps to protect finite resources and put sustainability at the center of their initiatives.

In 2022, The European Union reached a deal to cut net emissions and achieve climate neutrality by 2050. With the assumption that the US will adopt similar regulations, now is the time for companies to start prioritizing sustainability to get ahead of the curve.

“Circular economy” is a commonly referenced buzzword for sustainable business practices. In most cases, circular economy principles contrast with the OEM strategy to encourage refreshing or upgrading equipment every three years for efficiency. Newer generations of equipment may be energy efficient, but the reality is that extending life cycles results in lower carbon emissions versus replacing it with newer hardware. It can be challenging to sort through mixed messages.

The circular economy philosophy still applies when emphasizing the importance of slowing down the production and consumption of new materials. For example, when companies reuse, repair and extend the life of data center equipment, the materials, energy and pollution associated with new hardware decreases.

Before implementing strategies to take an eco-conscious approach to IT infrastructure, it’s essential to understand carbon emission scopes.

What are carbon emission scopes?

First established in 2001 by the Greenhouse Gas Protocol, “Scopes” categorizes the emissions companies create in their direct, indirect and overall supply chain. GHG Protocol uses Scopes 1, 2 and 3. Although not officially classified, Scope 4 is quickly gaining traction among companies measuring their emissions.

Scope 1: Direct emissions

These emissions are released directly from the company’s activities and operations, such as company-owned facilities and vehicles.

Scope 2: Indirect emissions (owned)

Includes emissions from purchased energy such as electricity, heating, cooling, etc.

Scope 3: Indirect emissions (not owned)

GHG Protocol separates Scope 3 emissions into upstream and downstream activities. Scope 3 is the most challenging category to measure and includes all emissions up and down a company’s supply chain.

--> Learn more about carbon scopes in Nordic Computer’s white paper.

Scope 4: Avoided emissions

As of 2022, Scope 4 isn’t officially recognized by GHG Protocol standards, but it illustrates that a company’s actions directly affect emissions. Scope 4 accounts for emissions saved or avoided outside a product’s life cycle or value chain. Examples of Scope 4 emissions are video conferencing products and services that enable employees to work remotely. These products reduce emissions created by employee commutes and other business travel.

Equipment life cycles and the carbon impact

What phase in the product life cycle generates the most emissions? OEMs promote decreasing CO2 emissions with newer, more energy-efficient equipment. But how does this type of strategy impact a company’s sustainability initiatives?

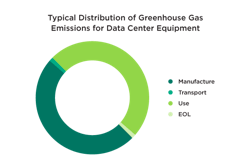

The image above illustrates the typical phases of data center life cycles.

Manufacturing: Covers every step from mining minerals and metals to the product’s final assembly.

Transportation: Distribution from the assembly site to the product location.

Use: The longest life cycle phase, representing the product’s operational life.

End of life (EOL): Disassembly, material recycling, incineration and landfill activities when the product is disposed.

The image above shows typical GHG emissions generated from each life cycle phase. Notice that emissions from the manufacturing and use phases are comparable. This general illustration applies for a range of data center hardware, including complete servers, hard disks, SSDs and more. It’s important to note this chart changes when companies utilize renewable energy sources. The findings above reinforce the importance of measuring the entire hardware life cycle instead of just the “use” phase.

--> Learn how to reduce the climate impact of data center hardware.

Reducing climate impact without compromising performance

Extending hardware refresh cycles by an additional 3-7 years lowers emissions and provides immediate relief from budget pressures. Since the equipment is already manufactured, prolonging its lifetime ownership to around 6-10 years slows the demand for new equipment.

IT leaders strive to extend equipment life cycles for sustainability and budget reasons, as outlined in the Service Express 2023 Data Center and Infrastructure Report. A longer equipment life benefits our planet and typically lowers IT costs without performance loss.

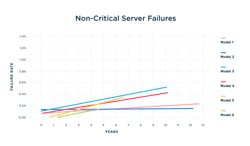

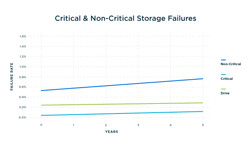

There are concerns about reliability when companies consider longer equipment life cycles. Service Express has collected over 15 years of data from over half a million devices to understand equipment longevity and reliability. The data tracks when, how and the frequency of critical and non-critical equipment failures.

The data samples above demonstrate hardware is reliable well past the 5-12-year mark. If equipment meets immediate needs, delaying an unnecessary refresh can help reduce CO2 emissions, decrease IT spending, extend the life of the hardware investment and more.

--> Read more: The Bathtub Curve and Data Center Equipment Reliability.

Making progress for our planet

Tackling challenges head-on requires determination, commitment, patience and the willingness to examine current processes. Every incremental change is a step forward in protecting and contributing to a more sustainable world. Service Express and Nordic Computer continue to offer expertise and support to help companies extend life cycles and prepare for future sustainability initiatives.

Jake Blough is CTO at Service Express and Lars Juhl Frandsen is the CEO at Nordic Computer. Contact Service Express to learn more.