Are Operators Ready for Green Data Center Laws?

According to a recent 2021 Uptime Institute global survey of over 400 data center owners and operators, only 38% of respondents believe that the industry’s environmental commitments are effective in curbing data center energy use, water use, and greenhouse gas emissions, while 45% of respondents believe that the industry’s commitments deliver few or no meaningful reductions in environmental impacts.

Despite this grim outlook, new sustainability laws have been on the horizon for quite some time now. In response, the Climate Neutral Data Centre Pact was signed in January of this year by 25 European data center operators and 18 trade organizations to self-regulate the industry with the goal of becoming climate-neutral by 2030.

Several large U.S.-based businesses, such as Google, Amazon Web services, and Equinix, have also signed this pact, indicating that the reach far extends the EU.

Journey to Sustainable Energy Usage

Pacts become nothing more than greenwashing if we do not take tangible, viable steps to create sustainable energy usage in operations. So, where do we start?

There are several contributing factors to inefficiencies in data centers, namely poor design, or poor operation of cooling systems. Significantly, new and changing IT equipment introduces a considerable amount of variability from a cooling standpoint.

Despite a growing understanding of best practices, it is still common to see an overuse of fans, wasted airflow, and even frigid conditions in data centers.

In this case, the first step to improving cooling efficiency starts with airflow. The best air-cooled data centers circulate just enough air to accomplish the primary goal of keeping servers stable. And the warmer the air, the more energy efficient (and cheaper) it is to cool.

Energy Efficiency is a Balancing Act

Data center performance is a delicate balance between capacity, efficiency, and compliance. Increasing efficiency by raising air temperatures without proper analysis can compromise the long-term capacity of the data center or put IT equipment at risk of failure.

With smaller server rooms, designing airflow may be as simple as following best practices. However, in a large data center with hundreds of server racks, owners and operators must go beyond the basic techniques we all know.

Airflow networks in larger, underfloor air systems are complex and can be tricky to balance. This is when advanced analysis becomes critical.

This advanced analysis must be able to answer the following questions: How much airflow do the servers really need? How high can the cooling temperature be without risking the health of the IT equipment? Why does a particular server see a lower inlet temperature than the one right next to it? And so on.

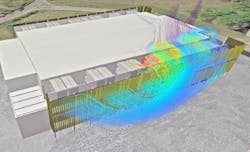

These answers can be found by creating a digital twin of your data center that can simulate airflow and temperature via Computational Fluid Dynamics (CFD). Simulation offers specific feedback regarding airflow patterns, which owners and operators can use to maximize cooling effectiveness without risk to IT.

The use of a data center digital twin allows you to find the optimal balance to improve energy efficiency and, in turn, maximize data center performance.

Mark Fenton is Product Manager at Future Facilities. Contact them to learn more about their digital twin technology.