Space Lasers, Smart Antennas Are Key Enablers for Satellite Broadband

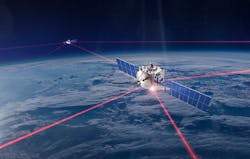

There’s a lot of innovation enabling satellite broadband delivery by companies like SpaceX and Telesat. Two leading-edge technologies are key to making low earth orbit (LEO) satellite broadband networks faster and more cost-effective: Lasers and actively electronically steered array (AESA) antenna. Rapid development of both are essential to reducing latency and cost.

Frickin’ Laser Beams

Laser links, or optical inter-satellite communications, are the basis of the next generation of SpaceX Starlink satellites, as well for Telesat and Amazon Project Kuiper satellites. Two companies to watch in this field are BridgeComm and Mynaric.

Using communications relays between satellites is nothing new. The currently operating Iridium network and in-deployment OneWeb satellites use radio links to move communications from satellite to satellite without having to use a relay station on the surface of the earth. That’s a key advantage when there is no affordable way to build a station in places like the middle of the ocean or at the poles. Using intersatellite links also reduces latency since packets aren’t passed through a ground station and terrestrial network connectivity to relay signals between satellite-connected locations in different parts of the world.

Similarly, the concept of free-space optical communications is nothing new in the telecom world, with terrestrial equipment providing high-speed point-to-point communications on the ground for several kilometers at up to gigabit class speeds in clear weather, with rain and fog slowing or blocking transmission – good for desert areas like Arizona or Nevada, less so in Seattle or Vancouver.

Security-conscious customers, such as the U.S. military and enterprises, prefer point-to-point laser communications because they are extremely hard to intercept when compared to RF.

Laser advocates cite two additional advantages for intersatellite links. Light travels 31 percent slower passing through fiber optic cable than a vacuum, so getting rid of the fiber as a transmission medium results in increased network speed. Secondly, point to point laser communications provides a true “straight line” path for data, instead of having to follow rights-of-way and other meandering paths that happen when fiber is pulled through conduits and deployed across the seabed.

The challenge for space lasers is being able to accurately point a light beam and keep it focused on a receiver with satellites flying at speeds of thousands of miles per hour and building space-qualified hardware in the quantities necessary for hundreds and thousands of satellites. Each satellite requires a minimum of four laser communications modules to network with satellites in front and behind of it in orbit and those to either side – think “left” and “right” relative to where the satellite is flying. Down the road, a fifth downward-pointing laser module may be incorporate to provide supplemental high-speed communication between the orbiting constellation and terrestrial networks.

The challenge for space lasers is being able to accurately point a light beam and keep it focused on a receiver with satellites flying at speeds of thousands of miles per hour.

Various on-orbit tests have taken and continue to take place to use lasers for both intersatellite and satellite-ground communications. SpaceX is the closest to rolling out intersatellite links on a production basis, having tested them on a pair of Starship satellites in 2020 and incorporated “v0.9” laser modules with a set of 10 satellites launched into polar orbit on January 2021. Lasers are expected to be standard equipment on all Starlink satellites sometime in the future. The company initially planned to have laser links on its first-generation satellites, but the technology wasn’t ready in the timeframe SpaceX needed.

Both Telesat and Amazon are incorporating lasers in their satellites from day one. OneWeb will likely incorporate laser intersatellite links in future generations of its satellites.

LEO’s Holy Grail – Low-Cost Antennas

Since LEO satellites are closer to the Earth, less power is needed for data transmission between ground and satellite and more data can be transmitted for any available amount of RF spectrum. However, “There ain’t no such thing as a free lunch” applies to LEO satellite constellations as much as any other technological advance. Lower orbits mean satellites fly across the sky faster, with a single satellite only overhead a couple of times a day for a handful of minutes.

To provide continuous 24×7 communications coverage, you need a “train” of satellites overhead, with “new” satellites coming into view as “old” ones leave and the ability to have antennas able to track multiple satellites at once.

Commercial users and cruise ships using the O3b MEO (Medium Earth Orbit) and OneWeb networks may use two to three mechanical antennas to track multiple satellites, but such operators have the luxury of enough physical real estate for multiple dishes and the service contracts to fix them when motors and gears break.

A BridgeComm antenna and ground station. (Image: BridgeComm)

Enter AESA, the actively electronically steered array (AESA) antenna. Many radio transmit/receive modules are placed into an array and use multiple managed beams to “track” satellites as they come across the sky instead of mechanically moving a dish. AESA was first used in military radars, resulting in higher reliability and much faster and accurate pointing along with a much flatter and smaller form than the traditional dish.

For LEO consumer and enterprise applications, AESA is a much more desirable solution than multiple physical antennas, but the sophistication and sheer quantity of circuits make it awfully expensive to build, with an antenna for a maritime vessel costs upwards of $20,000 and commercial aircraft antennas starting at $50,000 and quickly going higher.

How expensive and complex is an AESA antenna compared to other devices? A high-end cell phone may have anywhere from four radios and 13 antennas and list at $1,000 or so. The SpaceX Starlink AESA dish has over a thousand transmit/receive elements (radios) spread across a physical circuit board of 19.75 inches by 21.5 inches – a lot larger than a cell phone. One estimate by Business Insider pegged the cost of a Starlink dish to be around $2,400 in quantities of one million.

Amazon has shown some of its work in developing a lower cost AESA antenna for its Project Kuiper while Isotropic Systems and Kymeta Corporation are among the companies working with different technologies to drive the cost of antennas down. OneWeb and Telesat Lightspeed will need a healthy third-party antenna ecosystem for their LEO services to flourish since they aren’t building antennas in-house.

About the Author