The Interconnected World Places New Demands on Data Center Infrastructure: Are You Prepared?

Experts from Chatsworth Products explore how connectivity is changing the landscape for data centers and putting new requirements on data center infrastructure.

In the ever-evolving Information and Communications Technology (ICT) industry, protecting and securing equipment from the data center all the way to the edge can be a challenge. The rise of the Internet of Things (IoT) is requiring network connections to be stretched beyond the boundaries where electronics are normally deployed. Today, a soaring number of smart devices are processing real-time data in harsh or nontraditional environments, such as manufacturing floors, campus sites and outdoors. Meanwhile, in data centers—the core of the network—rack densities continue to increase. As a result, critical factors such as power management, cooling capacity and physical security take on even greater importance.

How will these trends impact the way you address ICT infrastructure? More importantly, how do you address the reality in which every network connection is critical?

As a global provider of products and services that protect critical ICT equipment, Chatsworth Products (CPI) proposes two important approaches that address both data center and edge deployments.

Many data center professionals still do not fully understand the long-term benefits of a full airflow containment strategy, so they continue to oversupply cold air to meet equipment temperature ratings.

When it comes efficiency within the data center, there is still is a good deal of misinformation in the marketplace regarding short cuts. For example, partial containment is widely deployed across the globe as a cost-saving measure to cooling capacity. The idea is to address the minimum necessary to gain efficiencies.

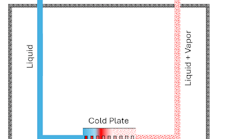

This misconception indicates that many do not yet grasp the benefits of passive cooling in reducing energy consumption and lowering construction and operational costs. There is a common perception that, for high-density environments, it is safer to deploy active cooling devices such as in-row cooling and air-to-water heat exchangers to meet cooling requirements. Many data center professionals still do not fully understand the long-term benefits of a full airflow containment strategy, so they continue to oversupply cold air to meet equipment temperature ratings. In most cases, full containment can give back up to 50 percent of existing cooling capacity without added cooling.

As an added challenge, rack densities are continuing to increase in many global markets. The greatest challenge for customers is managing available power within the rack so that all components in the power chain are meeting their power requirements.

Rack power distribution units (PDUs) represent the last leg of the chain, so having intelligent PDUs as part of your solution can be a game-changer, with one major component being the cost savings. For example, to manage a remote site, IT teams typically need to deploy one IP address for each cabinet. At an estimated $500 per port, having several or in some cases thousands of cabinets can get expensive. Look for intelligent PDUs that have Secure Array IP consolidation capability, which can link several PDUs (and cabinets) under a single IP connection. Outside the United States—where adoption for intelligent PDUs is slower—the significant cost-savings of IP consolidation should justify the upfront investment.

As such, it is important to take a more holistic approach to operations, one which addresses infrastructure, hardware and software as an ecosystem that simplifies equipment management and capacity in both on-premises data centers as well as remote sites.

Protecting Equipment at the Extreme Edge

As the network stretches to the edge, consider the environment in which equipment will be placed. Edge locations are not in environmentally controlled facilities like data centers, so protecting equipment in unique locations with varying environmental conditions (i.e., snow, humid, wet, salty or dusty environments) requires innovative methods of storage, support and maintenance.

Because they are in remote and sometimes extreme environments, networks at the edge are not administered or overseen daily. Like the proverbial chain that is only as strong as its weakest link, any limitations on network infrastructure, design or performance will result in unacceptable downtime. Environmentally rated enclosures and cooling accessories, and cable and power management solutions will play a key role in enabling network operations at the edge.

As a final note, it’s wise to invest in a comprehensive physical security solution that can be easily integrated into your edge enclosure. When planning for physical security, be sure to:

- Plan for multiple layers of security

- Ensure only authorized people have access to equipment

- Ensure data produced at the edge remains private

- Protect non-authorized users from being electrocuted

Properly planning and deploying such infrastructure can be a monumental task. For a successful edge investment, partner with suppliers who can provide customizable, scalable and environmentally rated solutions that can support and protect new-generation equipment.

These insights are just the tip of the iceberg. Demands and market conditions continue to change drastically throughout global regions. To learn more how each of these markets are responding to digital transformation, read CPI’s recent expert report on recommended strategies for 2019 and beyond.