ELK GROVE VILLAGE, Ill. – Inside its data center here in the western suburbs of Chicago, Forsythe Data Centers hopes to start a revolution in keeping IT equipment online. In an equipment galley, a cabinet houses a string of lithium-ion batteries for the uninterruptible power supply (UPS) keeping the power on at the data center.

Lithium-ion batteries are commonplace in devices like smartphones and laptop computers. But they’ve thus far been impractical in the data center, where banks of lead-acid batteries have been the standard choice for providing backup power during utility outages.

Although most data centers use lead-acid batteries, it doesn’t mean they love them. Maintenance is a particular headache, as batteries must be monitored and replaced as they fail.

“You begin replacing lead-acid batteries after three years, and do a wholesale replacement at five years,” said Thomas McKinney, Director of Data Center Development at Forsythe Data Centers, which is using a lithium-ion UPS system from Emerson Network Power. “With lithium ion, there are so many cells that you can’t lose a string. The failure risk is virtually non-existent.”

Potential Benefits of Lithium-ion UPS

At present, the primary alternative to lead-acid batteries has been UPS systems using a flywheel, a spinning cylinder which generates power from kinetic energy, and continues to spin when grid power is interrupted. Although a flywheel offers a shorter ride-through time (about 20 seconds), it eliminates the need for batteries. Yahoo, Verizon/Terremark and Oracle all use flywheel UPS systems, but some data center managers remain wary of their shorter run time than battery-based UPS systems.

Lithium-ion UPS systems could provide another option. Advocates of lithium-ion batteries cite multiple advantages over lead-acid batteries, including a longer lifetime, reduced weight and footprint, and less rigid cooling requirements. The primary resistance point is cost: lithium-ion systems are currently 2 to 3 times the cost of a valve-regulated lead-acid (VRLA) system at the same power level and runtime.

Data center operators are also cautious about introducing new technology in mission-critical gear like UPS systems, which provide temporary power when a facility loses power from the grid, keeping systems online until the emergency backup generators can start and assume the load. Before adopting something new, data center managers like to see it running successfully in someone else’s facility.

A lithium-ion UPS system from Emerson Network Power in action in the Forsythe Data Centers facility near Chicago. (Photo: Forsythe Data Centers)

That’s why early adopters like Forsythe are important, providing a working environment in which the new system can provie its worth alongside existing tech. The Liebert Lithium-Ion battery cabinets supporting Liebert NX UPS 300kVA systems were in beta when Forsythe began using them in mid-2015, but are now generally available.

Forsythe, which has been in the IT integration business for 45 years, didn’t bet the ranch on lithium-ion, either. The Forsythe Data Center maintains dual A and B power paths, with each UPS system supported by two Li-Ion battery cabinet strings on the A side and two VRLA battery cabinet strings on the B side.

The Lithium-ion UPS battery strings are approximately half the size and half the weight of the equivalent VRLA battery strings, according to Kevin Veseley, an associate project engineer at Forsythe, who says the lifespan and performance characteristics are also highly favorable for the Lithium Ion battery strings.

Emerson: A “Game Changing Innovation”

Leading UPS vendors believe Lithium-ion holds tremendous promise in improving UPS systems.

“Lithium-ion battery technology is a game-changing innovation for stored energy in the data center,” said David Sonner, vice president of North American power products for Emerson Network Power. “It delivers total cost of ownership benefits such as inherently longer life, which results in fewer replacements and lower maintenance costs. Capital efficiency is seen through improved use of space with smaller footprint and no unique ventilation requirements, lowering construction and installation costs, allowing Forsythe to pass these savings along to its own tenants.”

“While VRLAs remain the dominant UPS energy storage technology due to their low cost and high reliability, lithium-ion is becoming a more attractive option for a growing set of customers,” said Pedro Robredo, Vice President of Secure Power Systems, Schneider Electric. “While the initial cost remains higher than comparable VRLA, the price gap has reduced significantly in the last few years. Based on the application, Li-ion solutions can offer a projected Total Cost of Ownership savings from 10 percent to 40 percent over their design life.”

A UPS is Not a Smartphone

While it is actively marketing lithium-ion UPS systems and touting their benefits, Schneider notes that there are also challenges in the transition – including finding the right battery for the job.

“UPS requirements are quite different from those for, say, an electric car battery,” writes Patrick Brouhon, Strategic Marketing Director for 3-phase UPS, on the Schneider Electric blog. “Car batteries are designed to store lots of energy so the car can travel as many miles as possible before recharging. With UPS batteries, the concern is not length of run time so much as the need to deliver a lot of power quickly for a short period of time, usually just a few minutes until the backup generators kick in. For a UPS we’re also not really interested in a battery that can cycle on and off thousands of times, because a UPS kicks in only occasionally. Rather, we need it to be highly reliable and safe, with a long life expectancy.”[clickToTweet tweet=”Schneider Electric: Lithium-ion is becoming a more attractive option for a growing set of customers.” quote=”Schneider Electric: Lithium-ion is becoming a more attractive option for a growing set of customers.”]

An additional issue is federal regulations governing the transportation of products with lithium-ion batteries, which often preclude shipping by air. When improperly managed or stored, a lithium-ion battery can reach a thermal runaway state more easily, as it has a lower cell resistance and higher energy storage capacity than a lead acid battery. That’s why software for monitoring and managing the batteries is important in lithium-ion UPS systems.

Schneider notes that only a few years ago the cost difference was much greater, with lithium-ion running 10 times the price of lead-acid batteries, which are an “older, more mature technology with less of a chance of significant evolution occurring that would materially change the cost per kWhr much further downwards.” Schneider supports lithium-ion for its Symmetra MW, Galaxy 7000 and Galaxy VM UPS systems.

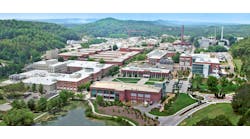

The exterior of the Forsythe Data Center facility in Elk Grove Village, Ill. (Photo: Forsythe Data Centers)

Design Considerations for Lithium-ion UPS

Lithium-ion UPS systems offer several other potential advantages. Lithium-ion batteries are less sensitive to temperature fluctuations and can accept changes in temperature. This allows customers to reduce their cooling capacity, as well as the size of the room that houses the UPS. It also offers additional design options, including in-row UPS deployments.

“It is now possible to get 6kW of power in a rack in a 2U package, weighing less than 100 pounds,” notes Emilie Stone, General Manager for Methode – Active Energy Solutions, in a column at Data Center Knowledge. “Rather than employing a heavily cooled and reinforced battery room, the UPS can be deployed in the rack or end-of-row to offer flexibility and simple power runs.”

Microsoft Gets Distributed

One company already using this approach is Microsoft, which has adopted a distributed UPS instead of centralized battery cabinets. Microsoft’s hyperscale solution is called Local Energy Storage, and uses lithium-ion battery cells on board each server – specifically, the Panasonic 18650 lithium ion cell, which has been used in rechargeable hand tools and is approximately the size of an AA battery.

Microsoft says it realized a 5x cost reduction over a traditional facility-level UPS, due to the simplification of the data center power chain, as well as moving the energy storage function to a high volume commodity supply chain.

While Microsoft was able to use commodity lithium-ion to reduce its costs, it is in a unique position in being able to design and build its own solution. For data center operators working with vendors providing UPS systems, cost will be an issue moving forward. In the meantime, the installation at Forsythe provides the industry with a look at the technology in action.

“We wanted to be the early adopter because we believe it’s so much better over the long run,” said McKinney. “If I felt I could get rid of every lead acid battery, I would do it immediately.”