Utility-scale energy storage has long been the missing link in the data center industry’s effort to power the cloud with renewable energy. A new project in Nevada will showcase a potential solution from Tesla, the electric car company led by tech visionary Elon Musk.

Data center technology company Switch will use new large-scale energy storage technology from Tesla to boost its use of solar energy for its massive data center campuses in Las Vegas and Reno. Switch broke ground this week on Gigawatt 1, a huge solar power project that will use First Solar photovoltaic panels to generate a total of 555 megawatts (MWs) of renewable power at three locations.

Switch says the project will feature one of the first large-scale installations of the Tesla Megapack, a new bulk energy storage product being manufactured at the Tesla Gigafactory, which is a Switch’s neighbor in a business park near Reno. Gigawatt 1 integrator Con Edison Clean Energy Businesses expects to use the Tesla Megapack to create more than 800 megawatt hours (MWhs) of energy storage capacity.

The Gigawatt 1 project, which was announced in 2018, underscore’s Switch’s commitment to running its operations with 100 percent clean energy, and showcases how the data center industry has taken a leadership role in shifting the U.S. economy to sustainable energy.

Energy storage could be a key enabler of that effort, allowing large users like data centers to overcome the intermittent generation patterns of leading renewable sources. Solar panels only generate power when the sun is shining, and wind turbines are idle in calm weather.

That’s a problem for data centers, which must provide uninterrupted power around the clock, in all weather conditions. Energy storage could address that gap, allowing renewable power to be stored for use overnight and on windless days.

Lithium-ion Energy Storage at Scale

The Megapack is a large-scale version of the lithium-ion battery storage systems that have recently gained traction in data center UPS systems. Each Megapack provides 3 megawatts of energy capacity and arrives pre-assembled and pre-tested in an enclosure from the Gigafactory, complete with battery modules, bi-directional inverters, a thermal management system, an AC main breaker and controls.

The price of lithium-ion batteries has fallen by about 80 percent over the past five years, according to the U.S. National Renewable Energy Lab (NREL), enabling the integration of storage into solar power systems. In the third quarter of 2019, the United States saw a 93% increase in the amount of storage deployed, compared to the previous year.

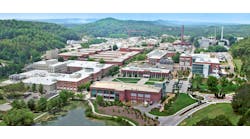

Switch says the Gigawatt project solar installation in Storey County will be the largest behind-the-meter solar project in the world, producing 127 MWs of solar energy to support the massive Switch Citadel Campus, and will include a 240 MW hour battery storage system. Behind-the-meter projects generate power off the public grid, placing no burden on legacy public utility production.

“With today’s announcement Rob Roy’s Gigawatt Nevada now has four solar with battery storage projects in the state creating nearly 1 gigawatt of energy solutions,” said Adam Kramer, Switch EVP of Strategy. “This project also ensures Switch’s power costs will remain in the 5 cent a KWh range and Switch clients will continue to enjoy low-cost, 100% renewable power for decades to come.”

The Megapack is a beefed-up successor to the PowerWall and PowerPack technology Tesla uses to support its electric vehicles. Each Megapack comes from the factory fully-assembled with up to 3 megawatt hours (MWhs) of storage and 1.5 MW of inverter capacity, building on Powerpack’s engineering with an AC interface and 60% increase in energy density to achieve significant cost and time savings compared to other battery systems and traditional fossil fuel power plants.

“As the world’s transition to sustainable energy continues to accelerate, the market for advanced battery storage solutions is growing rapidly,” Tesla said in announcing the MegaPack last year. “In the past year alone, we have installed more than 1 GWh of global storage capacity with our current storage products, Powerwall and Powerpack, bringing our total global footprint to more than 2 GWh of cumulative storage. With Megapack, this number will continue to accelerate exponentially in the coming years.”

“We are pleased to have collaborated with Tesla to install Megapack energy storage systems on four hybrid solar and storage projects in California and Nevada,” said Benoit Allehaut, Managing Director on Capital Dynamics’ Clean Energy Infrastructure team. “This selection was the result of a comprehensive due diligence process. We believe that industry leadership is achieved through scale and innovation and are pleased with the tremendous progress we have made in combined solar and storage plants thanks to Switch and Tesla.”